Michigan Tech Engineering Team Joins Open Source Ventilator Movement

Newswise - March 20, 2020 - As COVID-19 continues to spread, the research community is looking for solutions. In addition to work on vaccines and medicine, medical technology is needed. In severe cases of COVID-19, the disease attacks the respiratory system, and one of the major bottlenecks in treatment is having enough ventilators. The open-source hardware community wants to change that.

Joshua PearceJoshua Pearce, Richard Witte Endowed Professor of Materials Science and Engineering and a professor of electrical and computer engineering, is an open-source hardware expert and co-editor-in-chief of HardwareX, a leading open-source scientific hardware journal.

Joshua PearceJoshua Pearce, Richard Witte Endowed Professor of Materials Science and Engineering and a professor of electrical and computer engineering, is an open-source hardware expert and co-editor-in-chief of HardwareX, a leading open-source scientific hardware journal.

"The research on open-source ventilators is not new, but when it started a decade ago the technology was not there. Now it is, and we have substantial motivation, and we just need to bring all the information together," Pearce said, explaining that 3D-printed lab hardware and other open-source tech can be cost-effective and encourages design improvement. "Even complex medical devices are not outside the realm of possibility anymore."

Pearce, who runs the Michigan Tech Open Sustainability Technology (MOST) Lab, has joined the Michigan Tech Open Source Initiative, which collaborates with groups like the 9,000+ strong Helpful Engineers, made up of makers, hackers, medical personnel, engineers and other researchers from around the world. Many perspectives converge on a single goal: getting 3D-printed, open-source ventilators and other medical hardware where they're needed to overcome COVID-19.

However, technological expertise is not the same as medical expertise (and a key validation test for open-source ventilators requires a lab with a synthetic lung - not something most people keep around their makerspace). The end goal is medical-grade, low-cost designs, which can be made using distributed manufacturing technologies, like 3D printing or circuit milling systems, by anyone who needs them locally. To use them, the medical community needs certainty that an open-source design will operate as intended and do no harm.

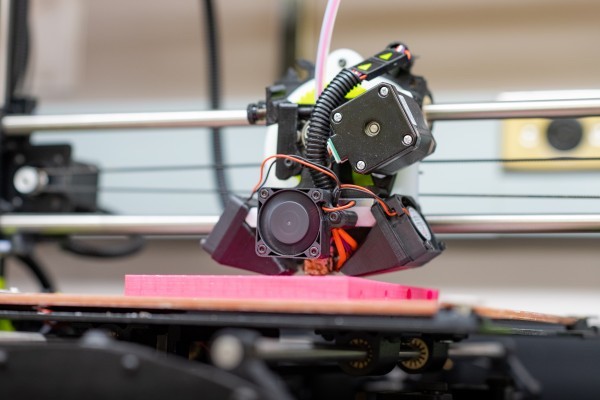

Using distributed technologies like 3D printing and circuit milling systems, makers around the world hope to build an open source ventilator - Michigan Tech

Using distributed technologies like 3D printing and circuit milling systems, makers around the world hope to build an open source ventilator - Michigan Tech

As the HardwareX editors write in their announcement, "This special issue is dedicated to vetting the technical specifications and reproducibility of open medical hardware that can help during this global pandemic."

They also note that, due to the urgency, Elsevier has made HardwareX platinum open access for the special issue, meaning all articles will be rapidly peer-reviewed and published open access upon acceptance, and all article processing charges will be waived. Or, as Pearce puts it for open hardware, "We need to test it, vet it and send it out to the universe."

The work is not clear or easy. Besides prioritizing remote work and social distancing like much of the working world, another limitation to combating COVID-19 is access to hardware. This includes ventilators, negative pressure rooms (airborne infection isolation rooms), oxygen concentrators, pulse oximeters, flow-splitters for oxygen supplies, flowmeters, nasal prongs/nasal cannulae, flexible nasal catheters, oxygen masks, non-contact thermometers, N95 respirators and powered, air-purifying respirators.

Even with uncertainty about whether manufacturing companies are willing to let open-source help out, there is immense pressure to get a design put together - and fast. As pointed out by the editor-in-chief of Science, the success of the world's recovery depends on what the research community is able to understand, mitigate and implement.

The technology enabling many of us to work at home is the same technology connecting the global open-source community. Their conversations are happening in Slack, on Facebook and through many, many emails. Lots of opportunities to get involved exist.

- Tags:

- 3D printed lab hardware

- 3D printed ventilators

- 3D printing

- airborne infection isolation rooms

- circuit milling systems

- complex medical devices

- cost effective technology

- COVID-19

- distributed manufacturing technologies

- flexible nasal catheters

- flow-splitters for oxygen supplies

- flowmeters

- global open source community

- HardwareX

- Helpful Engineers

- Joshua Pearce

- medical community

- medical expertise

- medical grade low cost hardware designs

- medical technology

- Michigan Tech Open Source Initiative

- Michigan Tech Open Sustainability Technology (MOST) Lab

- Michigan Technological University (MTU)

- N95 respirators

- nasal prongs/nasal cannulae

- negative pressure rooms

- non-contact thermometers

- Open Hardware

- open health

- open source

- open source design

- open source design improvement

- open source hardware

- open source hardware community

- open source medical hardware

- open source scientific hardware journal

- open source tech

- open source technology

- open source ventilator movement

- open source ventilators

- oxygen concentrators

- oxygen masks

- powered air-purifying respirators

- pulse oximeters

- technological expertise

- Login to post comments